AutoCoding benefits

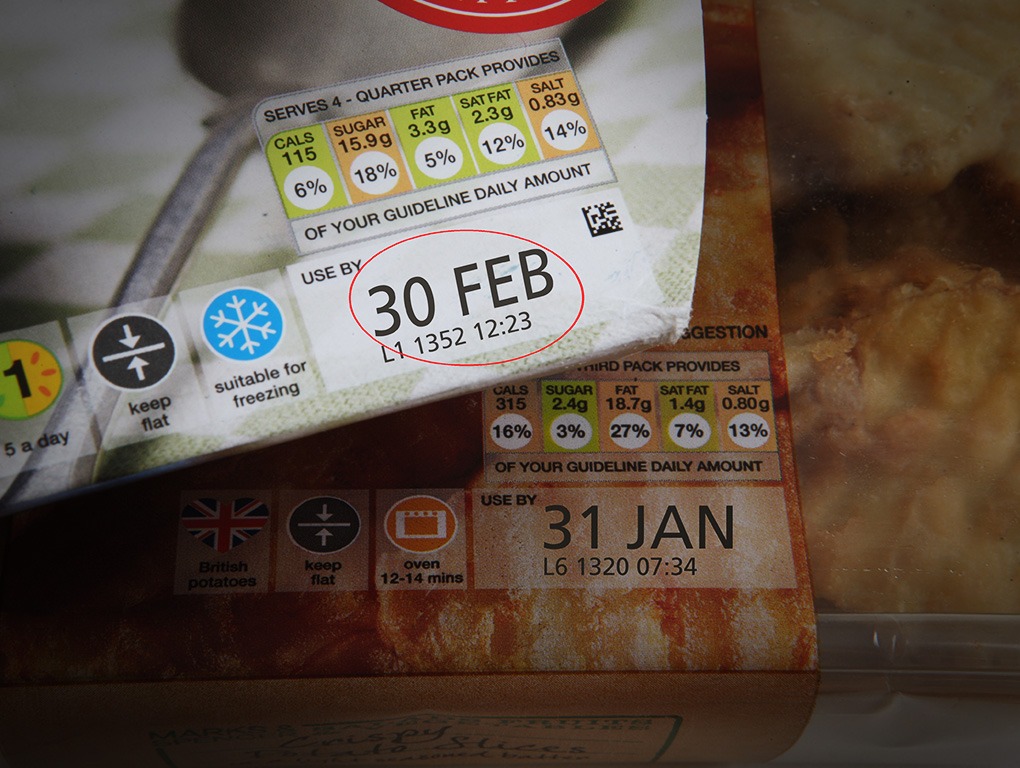

Controlled set-up of date coding equipment and deployment of data to the printers removes the risk of incorrect coding through operator error.

Automatic set-up of all packaging line devices via a line terminal reduces the job set-up and changeover time.

In-line barcode scanning of 1D and 2D barcodes provides verification that the product packaging and the artwork version are correct.

Seamless integration to the AutoCoding master database or an existing ERP or planning system ensures the product data is coming from a reliable source

Ingredients and allergens can be included in the scope of the AutoCoding system to reduce the risk of incorrect labelling – a common cause of product recalls

Controlling all the packaging line devices with one AutoCoding line terminal means operators only have to learn to work with one interface

Further benefits

Comprehensive line reports with a 100% audit log increases traceability and accountability

Line visualisation is possible via any web-enabled device, such as PC, tablet or Smartphone giving greater flexibility to monitor packaging line performance

Additional line devices can be integrated into the AutoCoding system easily resulting in a future-proof solution

The AutoCoding system can set up a single device or multiple lines and devices with the addition of further modules for increased functionality

User controlled access with validated data entry limits access of users to specific areas of the AutoCoding system, giving greater security

What people are saying about us

We have successfully worked with AutoCoding Systems since 2003 implementing their coding management system across all our lines. The system has proved to be reliable throughout this time, giving us the confidence to increase the scope into other areas.

Meeting the needs of a variety of customers has often resulted in a requirement for differing software functionality and the AutoCoding team has always risen to the challenge. We consider AutoCoding Systems to be valued partner to our business.