Benefits

Data embedded barcodes hold more information relating to the product than traditional 1D barcodes allowing better decisions to be made to reduce food waste

Smarter rotation of stock in store, ensuring shortest shelf life product is sold first

Smarter forecasting of demand to drive more efficient ordering to restock the store

Smarter management of price reductions to sell expiring product in a more timely manner

Ability to prevent out of date product being sold at the checkout

Challenges

Increased risk of setting up printers manually with incorrect information as there is an increase in the amount of information to be printed

Data embedded barcodes have to be read by point of sale scanners at check-outs, therefore a high quality of print is imperative

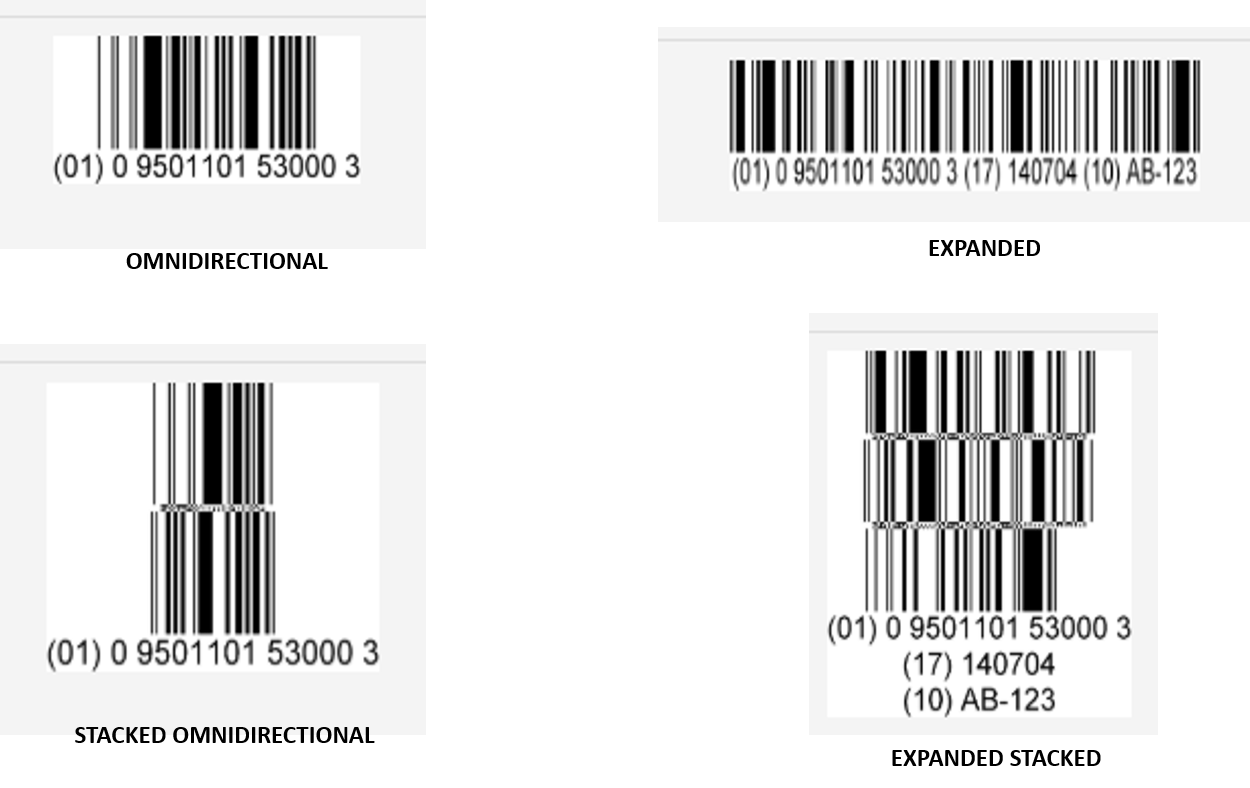

Additional space is needed on the product packaging for printing of the data embedded barcode, although there are different format options depending on the amount of information they contain

The AutoCoding packaging line control and coding verification solution can automatically set-up printers with this additional information and is capable of dealing with data embedded barcodes in the same way as traditional 1D and 2D codes.