Paperless Quality

Paperless Quality benefits

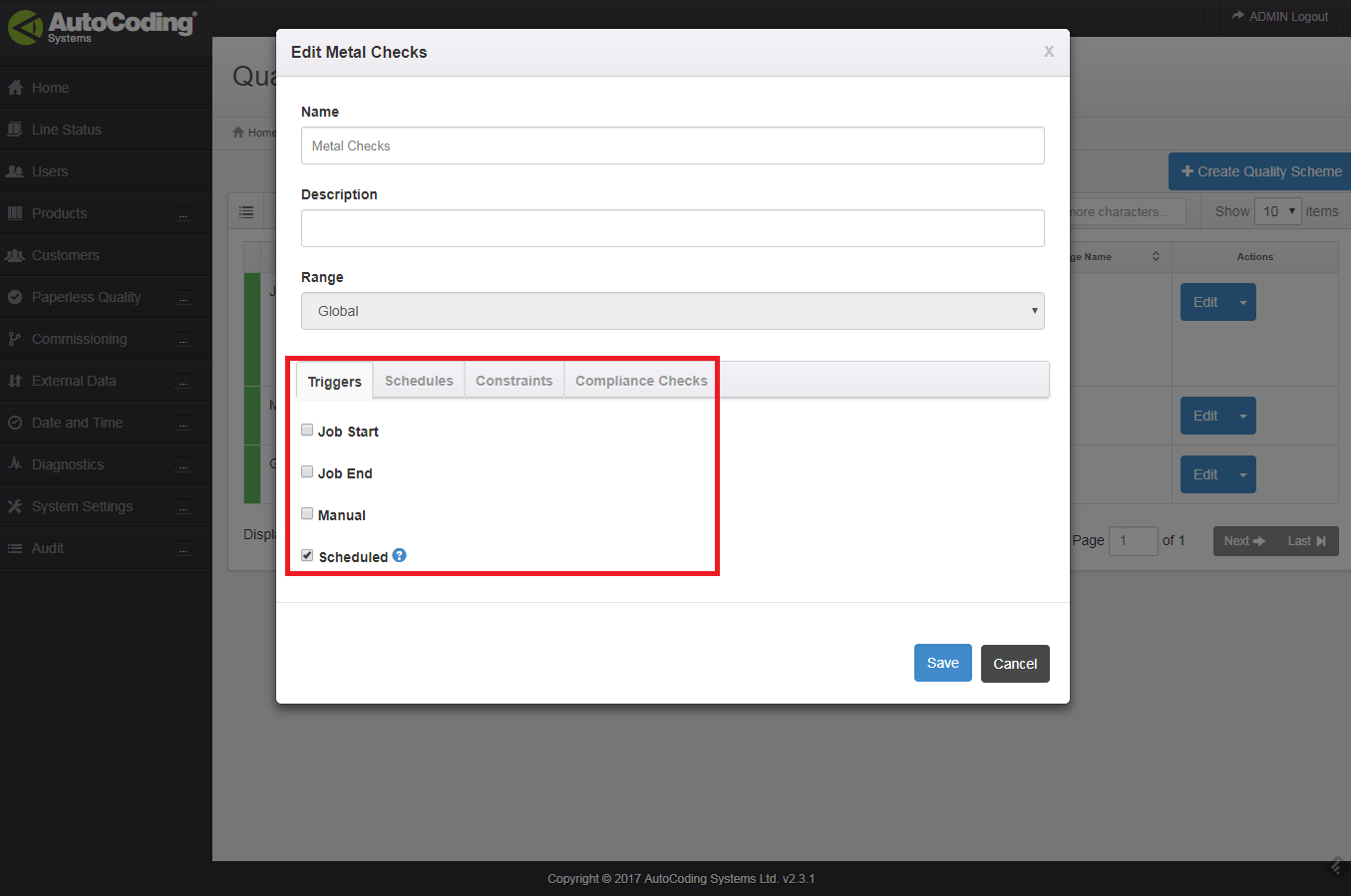

The system can be configured to individual requirements creating various methods for capturing quality data

A wide range of data variables can be incorporated such as weight, temperature, traceability codes, bake date etc

Webcams can be used to acquire digital images of products and coded information. These can be automatically saved for traceability purposes

Further benefits

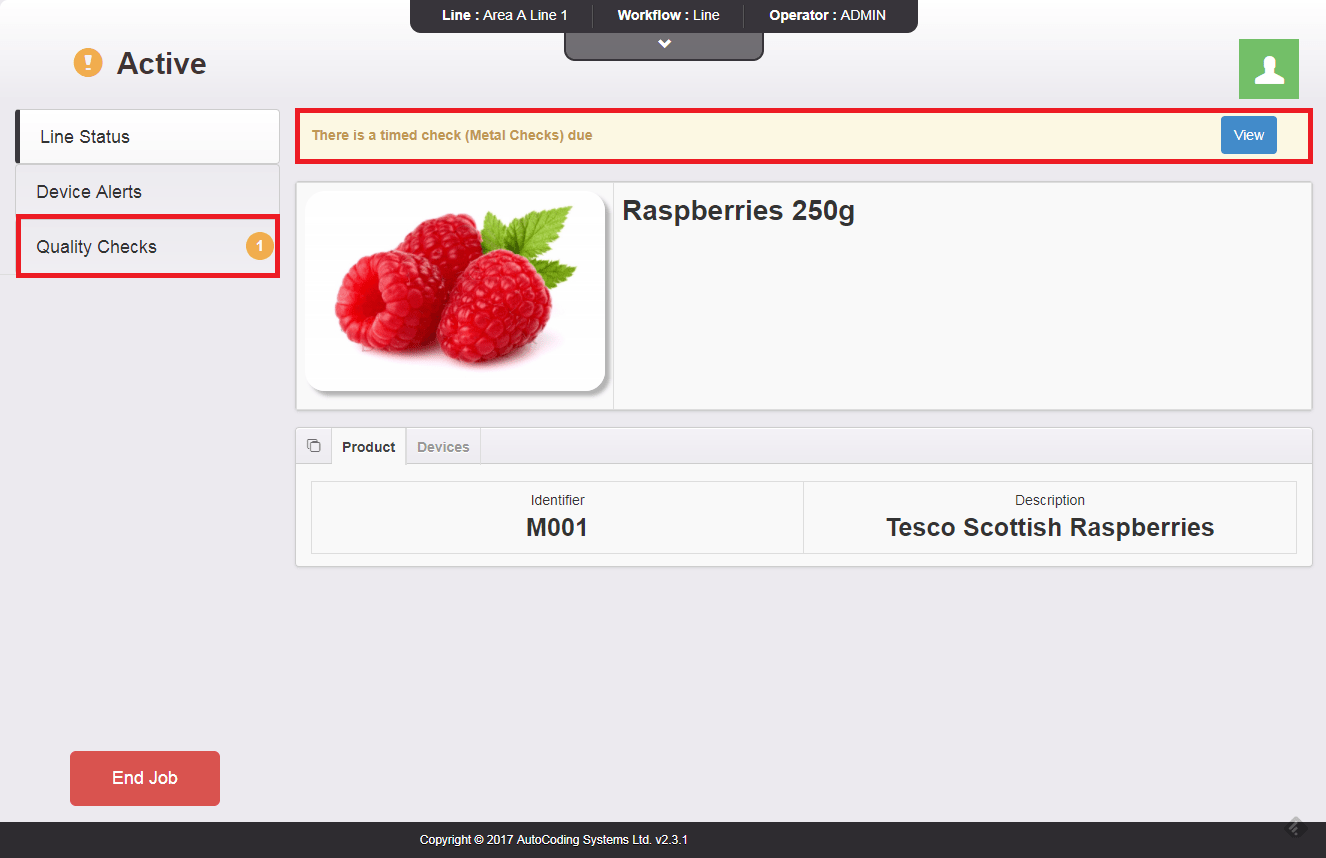

Specific time prompted checks can be included through a job run, the results of which can be saved, reducing paper records

All quality control events, both in-line and off-line, can be consolidated into the AutoCoding audit log improving traceability

By reducing a lot of the physical paper records of completed quality checks there is a corresponding reduction in storage requirements

What people are saying about us

“We have AutoCoding installed on 6 lines in our Newbury and Chester factories. The AutoCoding system integrates seamlessly with our Unity ERP system and manages the date code which is then applied by our coders. With the addition of online scanning of our packaging film and labels, we can be sure that our date coding and packaging will be correct at all times. We are now extending the system to include Paperless Quality to reduce the amount of paperwork we generate as part of our quality processes.”