Line Performance Reporting

Line Performance Reporting benefits

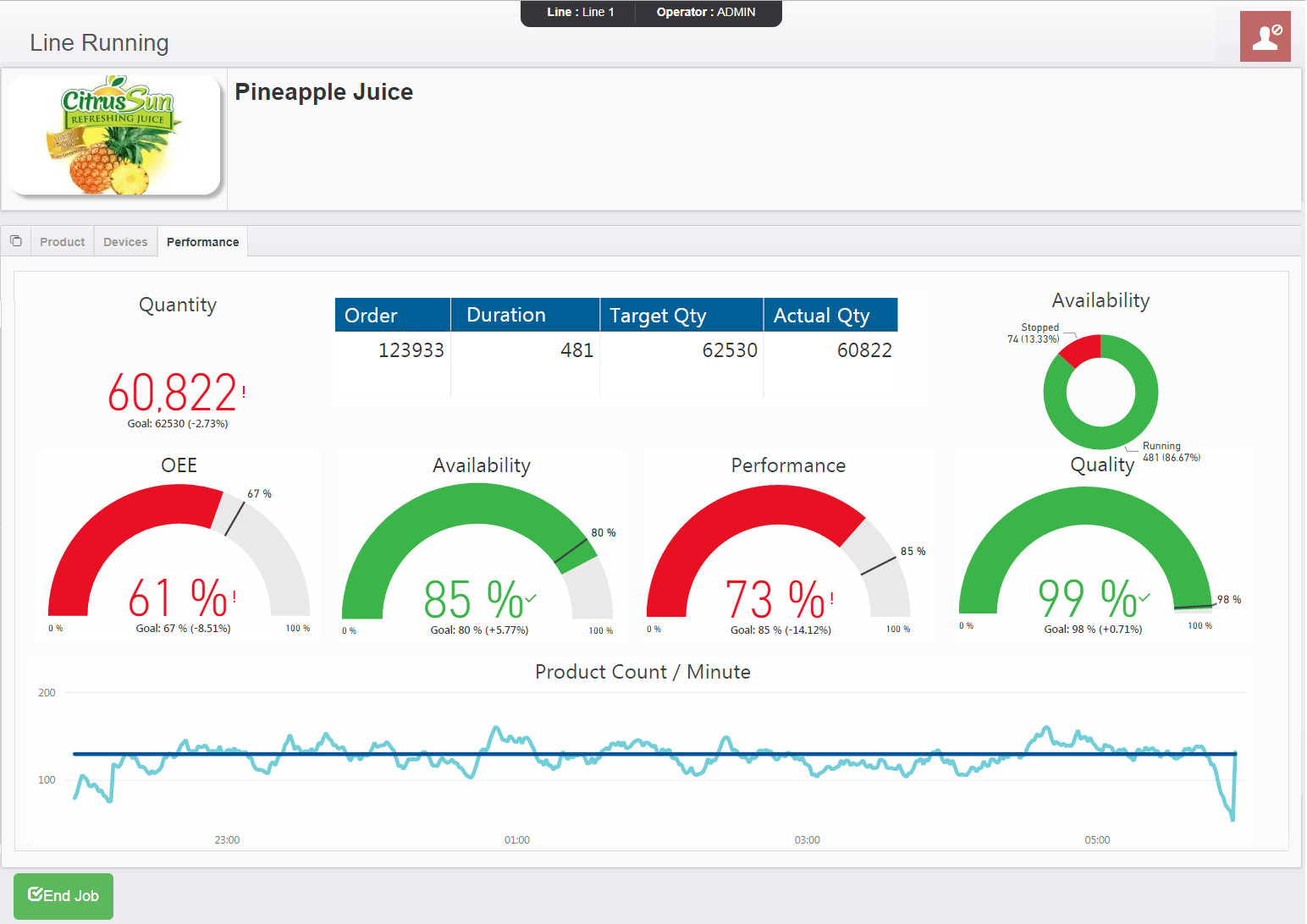

Consistently monitor the performance of your packaging line to ensure it’s running at the optimum line speed

Check quality and have transparency on how many products are scrapped or reworked giving you the information you need to resolve any issues, keeping costs to a minimum

Record availability so you can see exactly how much of the available production day is lost due to breakdowns or line stops. Record reasons for downtime resulting in visibility of recurring issues

Calculate OEE and measure the efficiency of your packaging lines

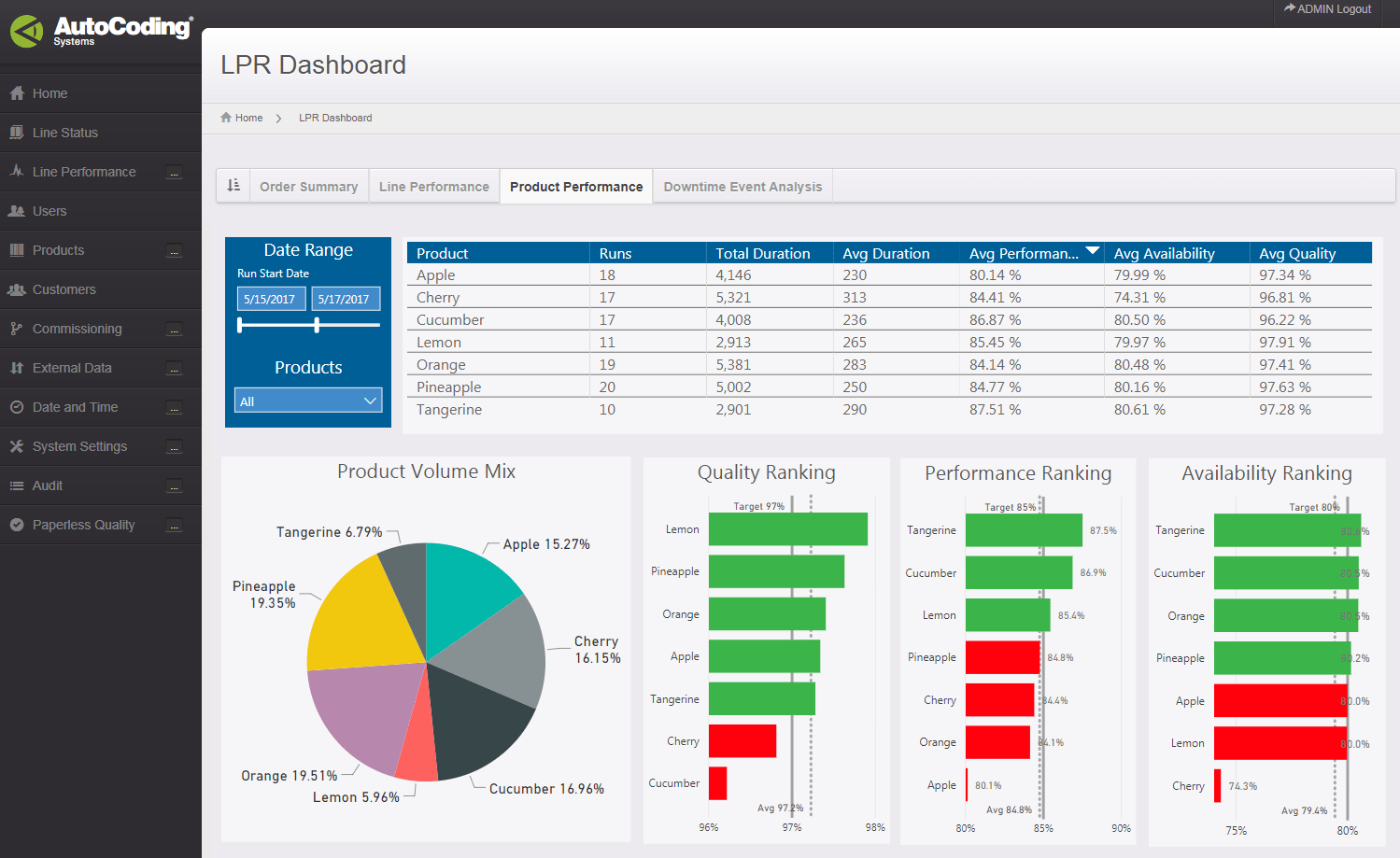

Performance by Product

- Number of runs, total/average duration, total/average production, by product

- Average performance, average availability, average quality by product

- Volume mix by product

Examples of Reports

Here are just some of the reports that can be created to give you accurate packaging line, device and product performance information:

Downtime Event Analysis

- Top downtime reasons by duration and frequency

- Percentage availability for a specific period

- Percentage efficiency by order run

Order Summary

- Product run with start and end time, duration and nominal targets

- Actual quantity and production trend

- Speed loss, stop loss, availability

What people are saying about us

“We are very happy with the detailed design and seamless implementation of the AutoCoding system. This solution has provided immediate benefits and we can see that the future expansion capability of the system will be a benefit to our business.”