Pallet Labelling System benefits

The open architecture of the AutoCoding Pallet Labelling System allows integration with any type of automatic labelling device, irrespective of brand, giving greater flexibility

Provides an interface between the packaging line and the warehouse management system as the solution is compatible with most data sources

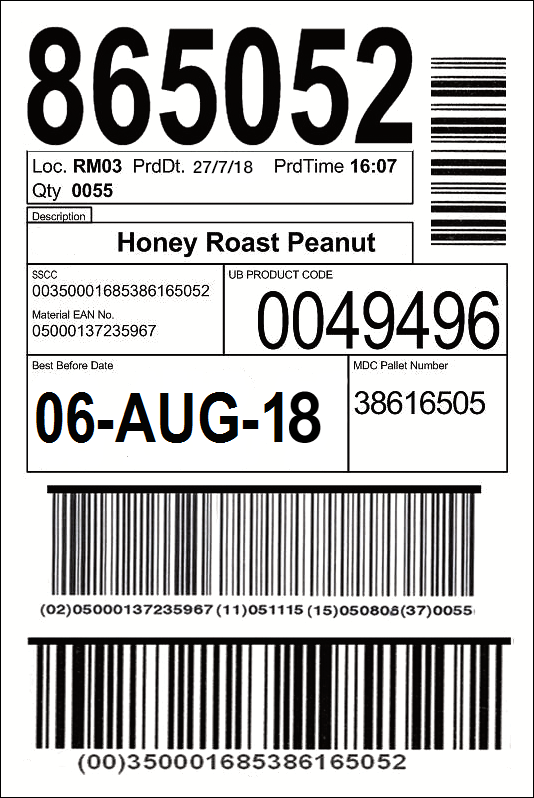

The system generates its own SSCC (Serial Shipping Container Code) for each product encoded in a barcode, together with information such as batch code, order identifier, line identifier and product code ensuring controlled and auditable pallet labelling

Further benefits

Accurately identifies pallets even if they arrive out of sequence from multiple lines ensuring controlled flow and correct delivery of pallets to the right location

Interacts and interfaces with all types of palletiser conveyor line controllers, such as Siemens and Allen Bradley

For added security, the system can accommodate a manual label station as back-up

Results in increased productivity, labour savings, reduced costs and improved speed or storage and retrieval in the warehouse

What people are saying about us

“AutoCoding Systems successfully delivered the AutoCoding Pallet Labelling System at the pilot site within a very tight timescale. Their technical expertise was invaluable and facilitated the seamless implementation. Following this success, the solution has now been rolled out to further factories and forms an integral component of the UBUK Warehouse Management System.”