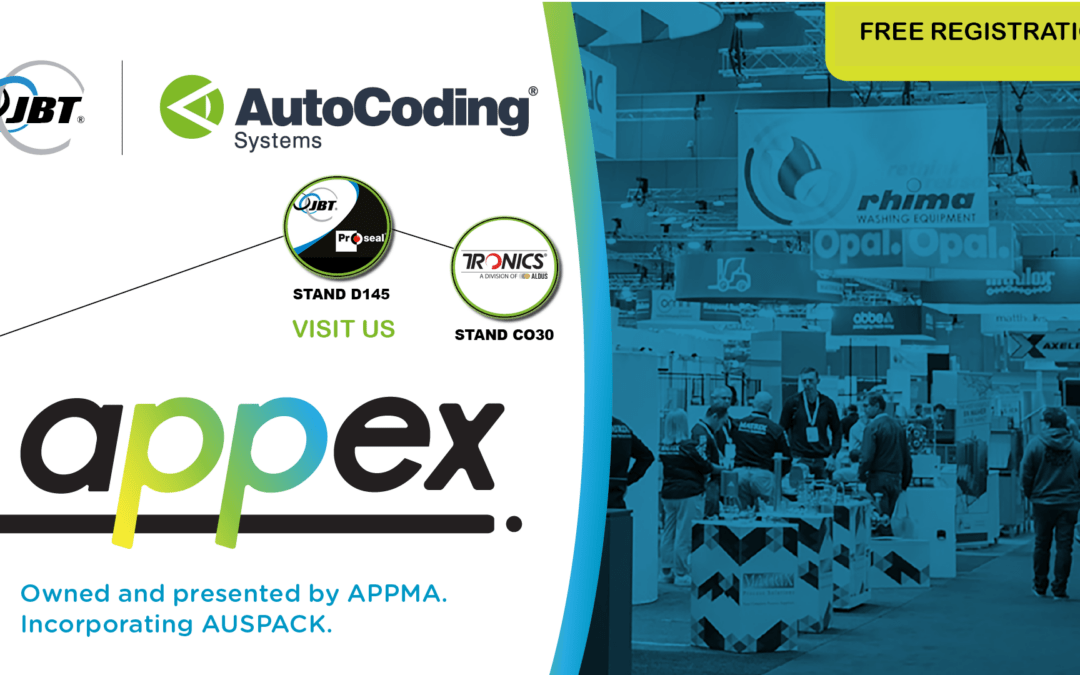

AutoCoding Systems PTY Ltd, a provider of packaging verification and date code control software solutions, is pleased to announce that it will be exhibiting on two stands at this year’s Australia’s Processing and Packaging Expo (APPEX) from 12-15 March 2024. Formerly known as AUSPACK, this event is set to be the largest B2B gathering for the processing and packaging sector ever held in Australia.

Seamless packaging line integration of tray sealing, control and digital tools

Together with JBT company, Proseal, AutoCoding Systems will demonstrate how the the AutoCoding software solution is integrated with Proseal’s tray sealing machine. The advantage of integrating a software solution that sets up and controls the devices on the packaging line with a tray sealer is that it ensures a seamless process at the primary packaging stage. Tray sealing parameters can now be sent from the AutoCoding database during recipe selection.

The Autocoding system automatically sets up the tray sealer and configures all the line devices on the packaging line during job setup, reducing start-up and changeover times and the need for human intervention. Autocoding prevents coding errors and integrated vision inspection systems on the packaging line verify label quality, presence and content, eliminating coding and packaging errors.

Mike Hughes, Managing Director of AutoCoding Systems, said, “I’m looking forward to attending the APPEX show. Since the company was established in Australia almost nine years ago, there has been a growing appetite for automation in the food industry. We’ve designed an automated system that can connect to equipment and devices, creating a seamless packaging line workflow on the factory floor.”

“In addition to packaging control, operators can perform real-time automated checks from the line terminal (HMI), or remotely via a web-enabled device. Supervisors can view comprehensive line reports and can have full traceability of all packaging line events through a digital audit log from our paperless quality module. Demand for these digital features is growing, as is the need to visualise the entire factory. This is where our Line Performance Reporting (LPR) module can benefit customers,” Mike added.

AutoCoding’s LPR module can display availability, performance and quality statistics in various modes of productivity reporting, including a conventional OEE metric. Through initial configuration, the system is set-up to capture downtime occurrences and allow the operator to select the root cause. During a shift, the reporting engine maintains a live dashboard view and historian reports are also available. The graphical reporting and visualisation is clear and concise and makes excellent use of modern web tools.

AutoCoding Systems will be demonstrating their software capabilities on the JBT, Proseal stand, D145.

Combining the latest technology and software updates in coding and labelling

AutoCoding Systems will also be exhibiting with technology partner Tronics, an Aldus company. They will be demonstrating their complete AutoCoding solution with their coding and labelling solutions. The AutoCoding system, including the patented 4Sight print inspection solution, can be seen in action with the latest generation of Tronics labelling and coding solutions on stand C030.

Visitors to the APPEX show can contact us to book a demonstration.

AutoCoding and Proseal are part of the JBT Corporation family, a leading global technology solutions provider to high-value segments of the food processing industry, committed to providing a service that surpasses customer expectations.