As we embrace the innovations and developments that 2024 may bring, it’s important for businesses to ensure optimal product safety and quality at all times. The Food Standards Australia New Zealand (FSANZ) agency has been responsible for collecting and examining all food recall information.

The rise in food recalls – a lagging indicator of quality systems?

Although there was a slight decrease of 3% in the number of product recalls in 2023 compared to the 75¹ product recalls in the previous year, the ten-year average of food recalls has increased. The moving average increased from a level of 79¹ recalls per year (2013-2022) to 82¹ recalls per year (2014-2023). The Ministry for Primary Industries, which oversees food management and regulation in New Zealand’s primary industries, also experienced a 33% increase in product recalls in 2023 from the previous level of 51² in 2022.

Food recalls are precautionary in nature. However, they do pose some risk to the end consumer, the root cause of which is predominantly related to packaging. Similar to safety indicators, they’re only identified once the event has occurred. Appropriate quality measures are often needed to prevent the risk of food recalls.

What leading indicators can be used to prevent food recalls?

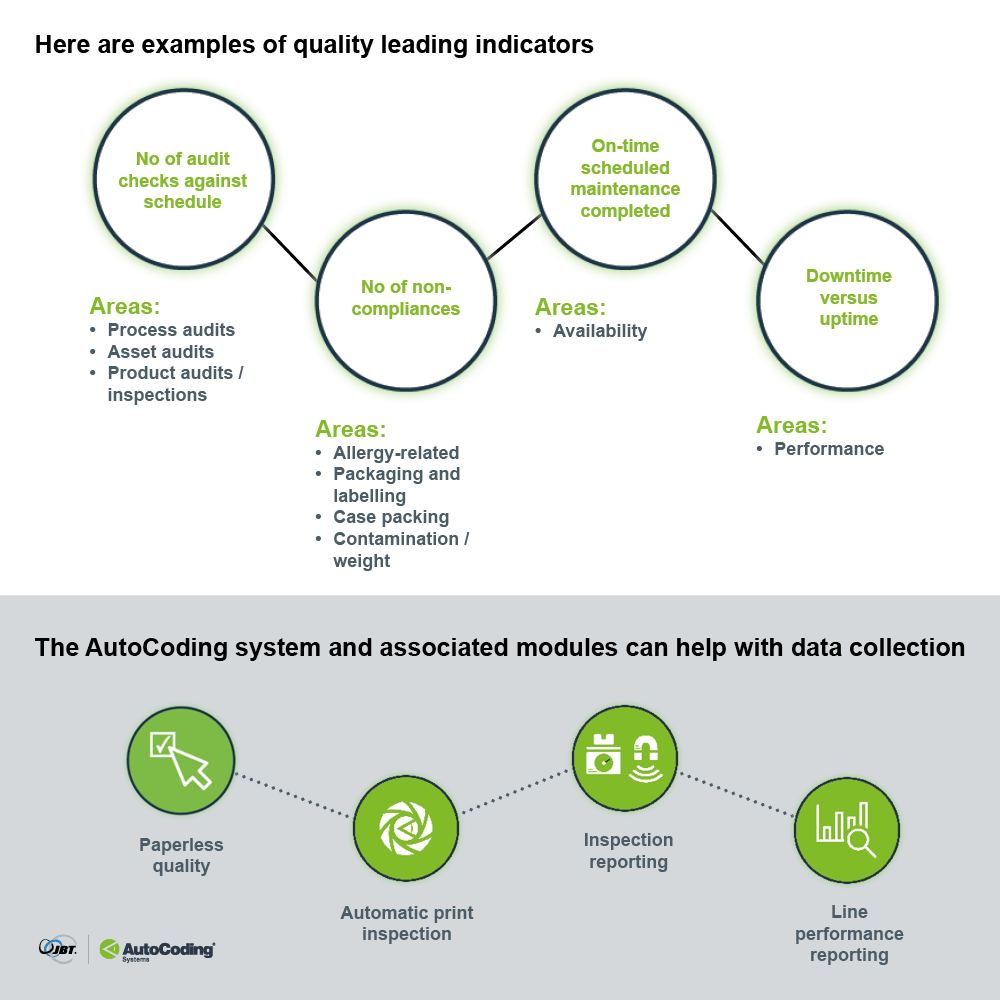

Leading indicators generally help to identify trends and patterns that may indicate the likelihood of future events. They can usually be influenced by internal initiatives and can be measured on an ongoing basis.

The AutoCoding system continuously monitors the packaging for the correct format, code, barcode quality and artwork content, from primary packaging to pallet labelling. The system can be monitored via the HMI (Human-Machine Interface) screen on the terminal, or remotely via a tablet or desktop PC. This control monitoring, with minimal human intervention, not only collects data, but also eliminates errors, reduces risk and improves set-up times for product labelling and packaging.

For a more detailed view of how AutoCoding system solutions capture data to support these leading indicators – click here.

Demonstration of the AutoCoding System at #appex2024

Australasian Processing and Packaging Expo, 12 – 15 March 2024, Melbourne Convention and Exhibition Centre

If you’d like to find out more about how AutoCoding can minimise the risk of a product recall, AutoCoding Systems will be attending the Australia’s Processing and Packaging Expo (APPEX) which takes place from the 12th to the 15th of March 2024. Formerly known as AUSPACK, this event is set to be the largest B2B gathering for the processing and packaging sector ever held in Australia.

You can see us at two stands. Join us at our sister company Proseal’s stand on D145 to see our AutoCoding system in action. Our AutoCoding solution has been integrated with Proseal’s tray sealing machine to provide a seamless packaging experience. The AutoCoding system can work with an existing MES (Manufacturing Execution System), enabling the sharing of business system information, which is made possible by our AutoCoding Gateway.

Alternatively, our system can be seen in action on stand CO30 with the latest generation of labelling and coding solutions from Tronics, an Aldus company.

Contact us and speak to a member of the AutoCoding Systems team to learn about our solutions.

AutoCoding and Proseal are part of the JBT Corporation family, a leading global technology solutions provider to high-value segments of the food processing industry, committed to providing a service that surpasses customer expectations.

What is AutoCoding?

Sources:

- Food Standards Australia New Zealand, 6 December 2023, ‘Food recall statistics’, FSANZ, CC By 3.0 AU Deed, Food recall statistics | Food Standards Australia New Zealand and Australian food recall alerts | Food Standards Australia New Zealand

- Ministry for Primary Industries and licensed by MPI for re-use under the Creative Commons Attribution 4.0 International licence, 5 February 2024, ‘List of food recalls from 2015 to 2023’ Recalled food products list | NZ Government (mpi.govt.nz)